By renxin-precision | 25 October 2023 | 0 Comments

Extruded Profile Heatsinks – The Best Solution for Your Thermal Management Needs

Thermal management is an important aspect in today's electronics industry. The proper functioning and longevity of electronic products depend greatly on their ability to dissipate heat effectively. With the continuous development of advanced electronics technology, the requirement for high-performance thermal management has increased tremendously. The thermal management system encompasses many heat transfer technologies, including passive and active heat sinks. Amongst these, the use of extruded profile heatsinks stands out.

In this blog post, we will explore the potential of aluminum extrusions profiles, popularly known as extruded profile heatsinks. We will take you through what they are, how they work, their applications, and the benefits that they can offer. We will also suggest how best to select the right extruded profile heatsinks for your product. This comprehensive guide will give you an in-depth understanding of the role of extruded profile heatsinks in ensuring the optimal thermal management of your electronic products.

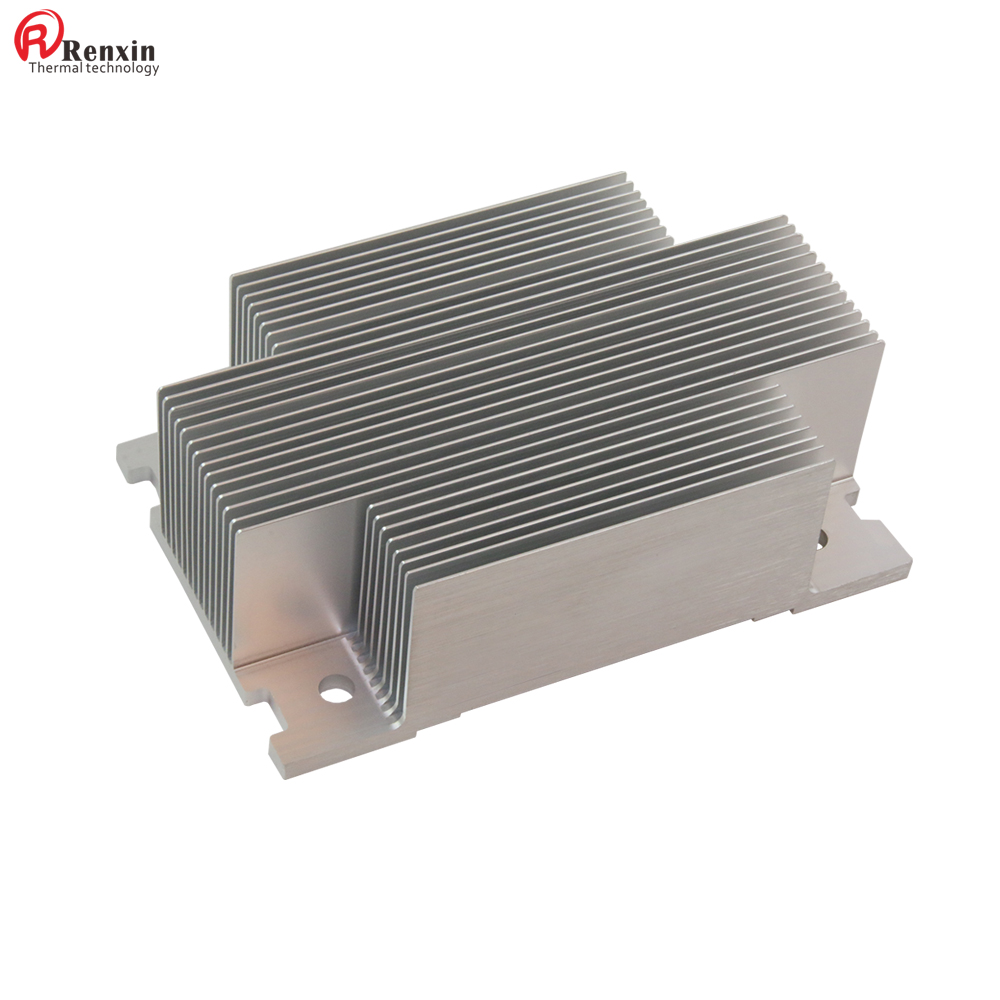

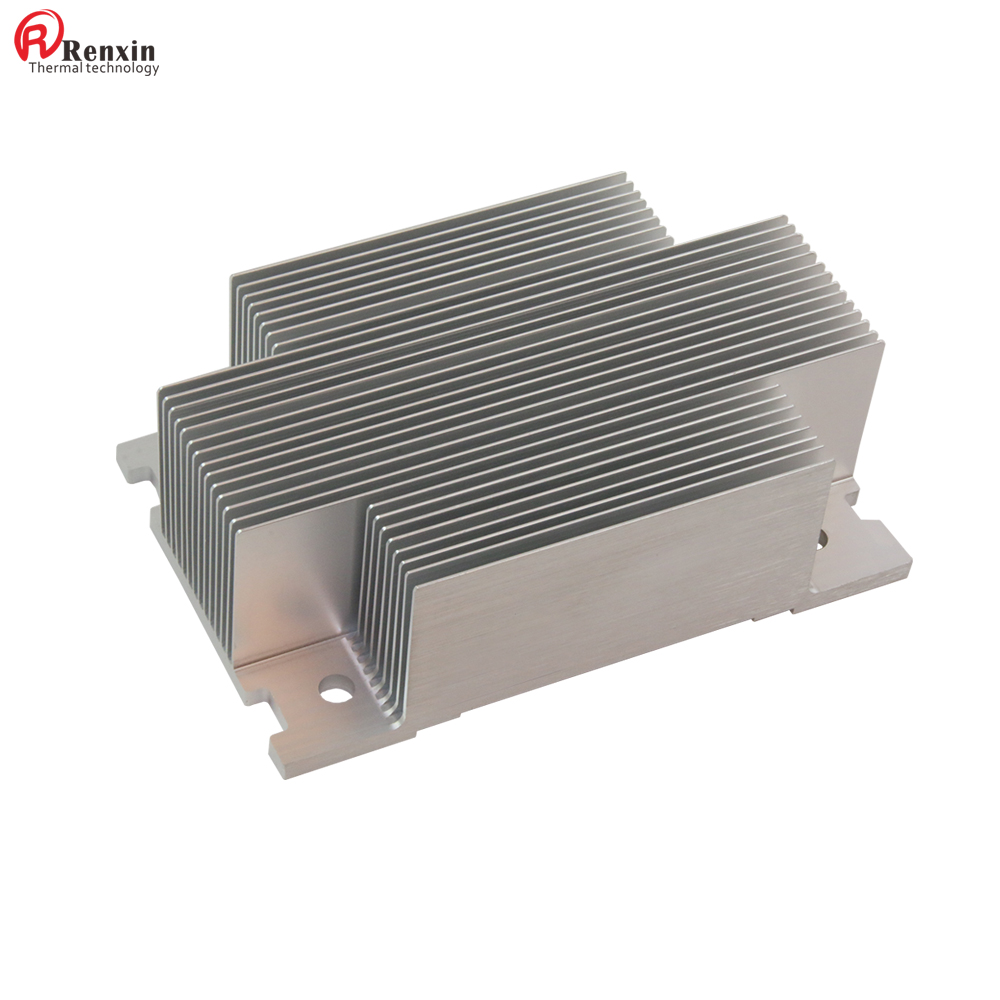

1. What are Extruded Profile Heatsinks?

Extruded profile heatsinks, commonly referred to as aluminum extrusions profiles, are one of the most popular heat dissipation solutions used in electronics. They are manufactured by shaping aluminum billets into desired shapes using a specialized extrusion process. This process utilizes a heated aluminum billet pushed through a pre-designed die and pressed into the desired shape. The final product is a custom-shaped heat sink that allows for maximum thermal dissipation and surface area.

2. How Do Extruded Profile Heatsinks Work?

Extruded profile heatsinks are designed to provide a conductive path for heat to transfer from the source to the ambient environment. They achieve this through their high thermal conductivity and surface area. The heat produced by a component, such as an LED or a microprocessor, is conducted through the base of the heatsink, which has a high thermal conductivity. The fins on the heatsink then provide a greater surface area, which allows for more heat to be dissipated into the surrounding air. The effectiveness of the heatsink increases with an increase in fin density and the use of a fan to assist with heat dissipation.

3. Applications of Extruded Profile Heatsinks

Extruded profile heatsinks have numerous applications in the electronics industry. They are commonly used in power supplies, motor controllers, LED lighting, computers and other electronic devices that generate heat. They are also widely used in the automotive industry, either to cool engine components or to keep cabin interiors cool. With the increasing demand for high-performance and energy-efficient cooling solutions, the potential uses of extruded profile heatsinks continue to expand.

4. Benefits of Extruded Profile Heatsinks

Extruded profile heatsinks offer several advantages over other forms of heat dissipation solutions. Firstly, they are highly customizable, and can be designed to any shape and size with various fin densities or fan configurations. Secondly, they are cost-effective and energy-efficient. Their low tooling and setup costs make them very economical, and their high thermal conductivity allows for the use of low-power fans to aid in heat transfer. Thirdly, extruded profile heatsinks are lightweight and compact, making them ideal for use in highly constrained spaces.

5. Selecting the Right Extruded Profile Heatsink

When selecting the right extruded profile heatsink for your product, there are several factors that you should consider. These include the nature of the equipment, the thermal requirements and the available space for installation. Other factors to consider are the ambient temperature, the airflow rate and the type of cooling fan needed. It’s essential to work with a reputable supplier such as Renxin Precision, who can provide you with expert advice and customized extruded profile heatsinks to meet your specific needs.

Extruded profile heatsinks are an excellent solution for thermal management in the electronics industry. With their high thermal conductivity, customizability, low cost, and energy efficiency, they have become an indispensable component in the design of electronic products. Finding the right supplier who can provide you with expert advice goes a long way in ensuring that you get the perfect fit for your heat dissipation solution. If you’re looking for a reliable supplier of extruded profile heatsinks, contact Renxin Precision today. E-mail: sales@renxin-precision.com or Tel:+86(769) 8182 2159.

In this blog post, we will explore the potential of aluminum extrusions profiles, popularly known as extruded profile heatsinks. We will take you through what they are, how they work, their applications, and the benefits that they can offer. We will also suggest how best to select the right extruded profile heatsinks for your product. This comprehensive guide will give you an in-depth understanding of the role of extruded profile heatsinks in ensuring the optimal thermal management of your electronic products.

1. What are Extruded Profile Heatsinks?

Extruded profile heatsinks, commonly referred to as aluminum extrusions profiles, are one of the most popular heat dissipation solutions used in electronics. They are manufactured by shaping aluminum billets into desired shapes using a specialized extrusion process. This process utilizes a heated aluminum billet pushed through a pre-designed die and pressed into the desired shape. The final product is a custom-shaped heat sink that allows for maximum thermal dissipation and surface area.

2. How Do Extruded Profile Heatsinks Work?

Extruded profile heatsinks are designed to provide a conductive path for heat to transfer from the source to the ambient environment. They achieve this through their high thermal conductivity and surface area. The heat produced by a component, such as an LED or a microprocessor, is conducted through the base of the heatsink, which has a high thermal conductivity. The fins on the heatsink then provide a greater surface area, which allows for more heat to be dissipated into the surrounding air. The effectiveness of the heatsink increases with an increase in fin density and the use of a fan to assist with heat dissipation.

3. Applications of Extruded Profile Heatsinks

Extruded profile heatsinks have numerous applications in the electronics industry. They are commonly used in power supplies, motor controllers, LED lighting, computers and other electronic devices that generate heat. They are also widely used in the automotive industry, either to cool engine components or to keep cabin interiors cool. With the increasing demand for high-performance and energy-efficient cooling solutions, the potential uses of extruded profile heatsinks continue to expand.

4. Benefits of Extruded Profile Heatsinks

Extruded profile heatsinks offer several advantages over other forms of heat dissipation solutions. Firstly, they are highly customizable, and can be designed to any shape and size with various fin densities or fan configurations. Secondly, they are cost-effective and energy-efficient. Their low tooling and setup costs make them very economical, and their high thermal conductivity allows for the use of low-power fans to aid in heat transfer. Thirdly, extruded profile heatsinks are lightweight and compact, making them ideal for use in highly constrained spaces.

5. Selecting the Right Extruded Profile Heatsink

When selecting the right extruded profile heatsink for your product, there are several factors that you should consider. These include the nature of the equipment, the thermal requirements and the available space for installation. Other factors to consider are the ambient temperature, the airflow rate and the type of cooling fan needed. It’s essential to work with a reputable supplier such as Renxin Precision, who can provide you with expert advice and customized extruded profile heatsinks to meet your specific needs.

Extruded profile heatsinks are an excellent solution for thermal management in the electronics industry. With their high thermal conductivity, customizability, low cost, and energy efficiency, they have become an indispensable component in the design of electronic products. Finding the right supplier who can provide you with expert advice goes a long way in ensuring that you get the perfect fit for your heat dissipation solution. If you’re looking for a reliable supplier of extruded profile heatsinks, contact Renxin Precision today. E-mail: sales@renxin-precision.com or Tel:+86(769) 8182 2159.

Leave a Reply

Your email address will not be published.Required fields are marked. *

POPULAR BLOG

- Custom Solutions in Extruded Profile Heatsinks

- Optimizing PCB Performance with Extruded Heatsinks

- Why Aluminum Extrusions Profiles are Essential for PCB Board Level Heatsinks

- Everything You Need to Know About Extruded Profile Heatsinks

- Extruded Profile Heatsinks – The Best Solution for Your Thermal Management Needs

CATEGORIES