By renxin-precision | 07 November 2023 | 0 Comments

Why Aluminum Extrusions Profiles are Essential for PCB Board Level Heatsinks

As technology continues to advance, the need for efficient cooling solutions for devices such as mobile phones, laptops, and gaming consoles, also increase. One way to achieve optimal cooling is by using aluminum extrusions profiles. In this blog post, we will discuss why aluminum extrusions profiles are essential for PCB board level heatsinks, how they work, and where to get them.

1. What are Aluminum Extrusions Profiles?

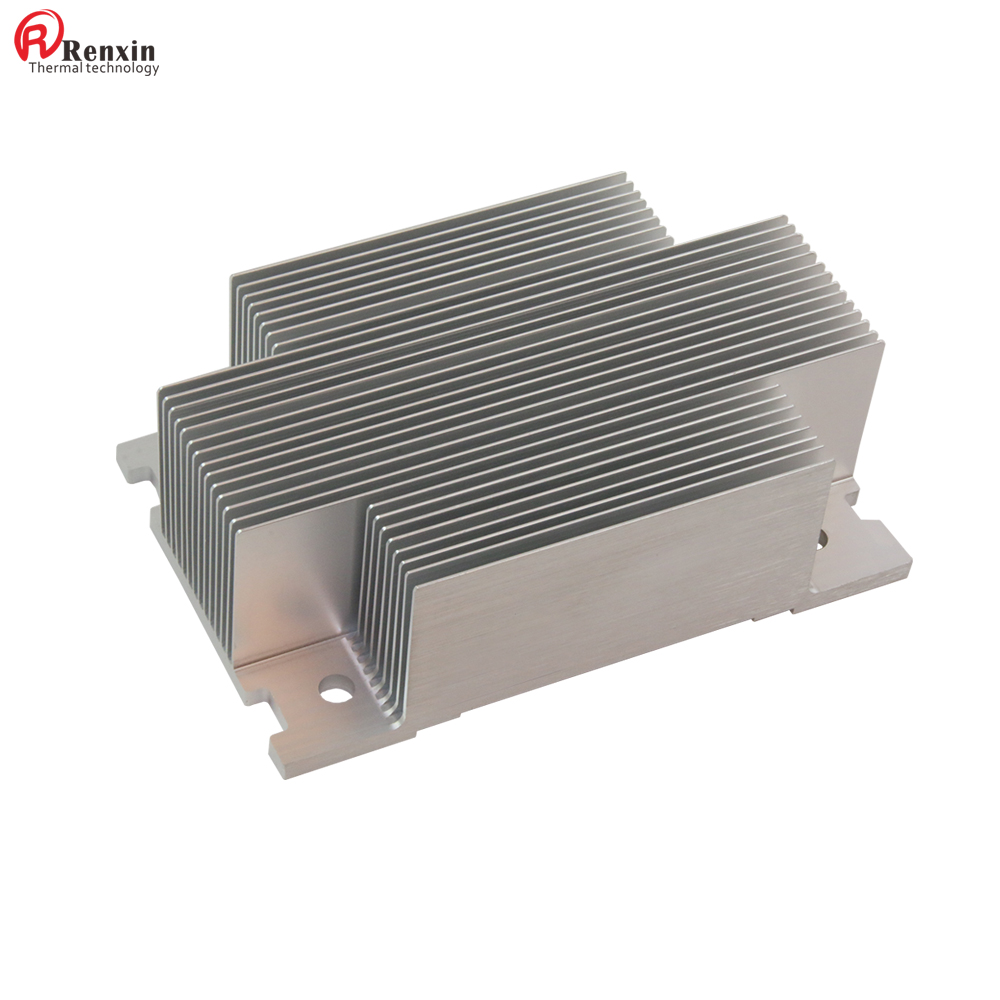

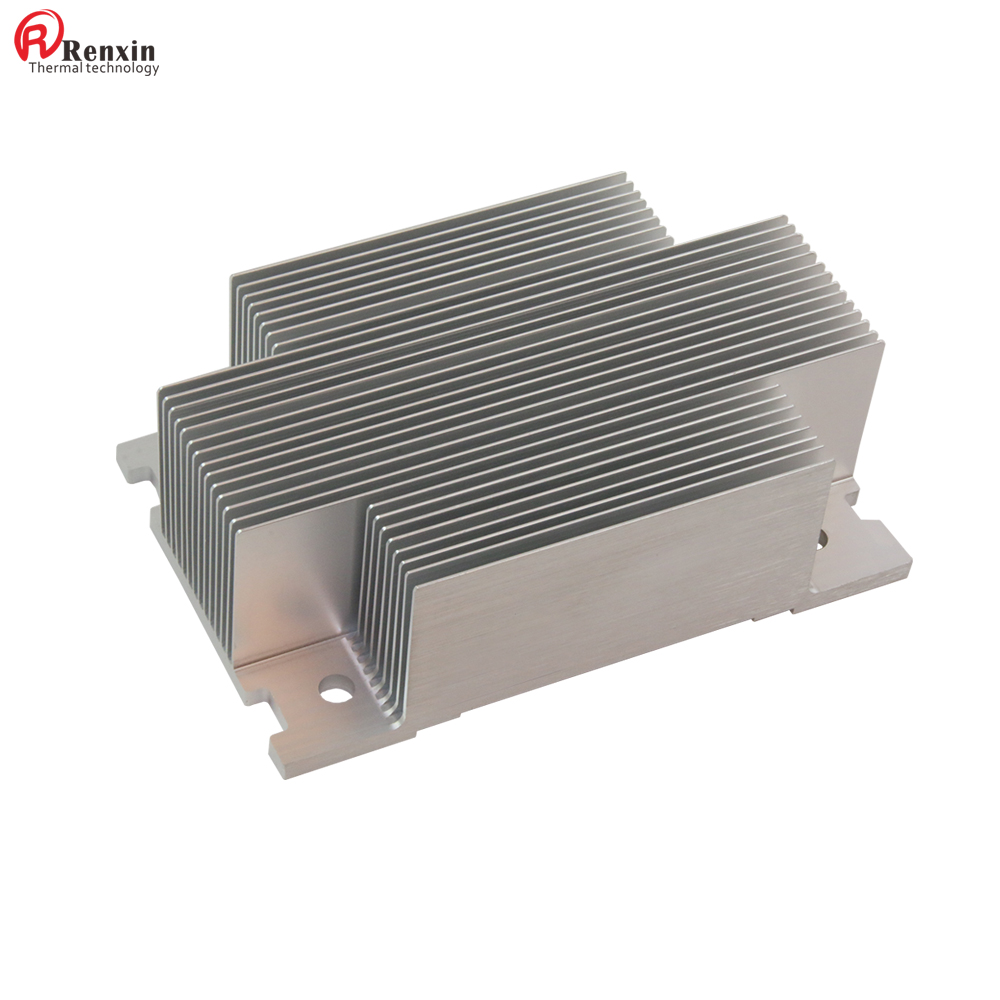

Aluminum extrusions profiles are pieces of aluminum that have been shaped into a specific design using a manufacturing process called extrusion. The process involves pushing heated aluminum material through a die to create the desired shape. The result is a uniform cross-section profile that is strong, easy to handle, and has excellent heat dissipation. These profiles come in different shapes and sizes, making them versatile and suitable for various applications.

2. How do Aluminum Extrusions Profiles Work in PCB Board Level Heatsinks?

Electronic devices generate heat during operation, which can cause damage to the components if not well managed. PCB board level heatsinks are used to help dissipate the heat away from critical components on the board and keep the device running efficiently. Aluminum extrusions profiles are essential in making these heatsinks because they have high thermal conductivity, which helps transfer the heat away from the hotspots on the board. The profiles' uniform cross-section design allows for efficient airflow, dissipating heat faster than other heat sink materials.

3. Benefits of Using Aluminum Extrusions Profiles for PCB Board Level Heatsinks

a) High Thermal Conductivity - The material's high thermal conductivity helps transfer heat away from the hot spots on the board and into the surrounding environment.

b) Efficient Heat Dissipation - The uniform cross-section design of the extruded profile heatsink allows for optimal airflow, dissipating heat faster than other heat sink materials, resulting in better cooling performance.

c) Cost-Effective - Aluminum extrusions profiles are cost-effective compared to other materials used for making PCB board level heatsinks such as copper. They are also lightweight, which makes them easy to handle.

d) Versatility - The profiles come in various shapes and sizes, making them versatile and suitable for various applications.

4. Where to Get Quality Aluminum Extrusions Profiles for PCB Board Level Heatsinks

If you are looking for quality aluminum extrusions profiles for your PCB board level heatsinks, Renxin Precision is your best bet. Renxin Precision is a leading aluminum extrusions profile manufacturer that specializes in producing high-quality extruded profiles. They use modern extrusion machinery to ensure that their products are of high quality and meet the industry standards. They also offer a wide variety of profiles to choose from, depending on your needs.

In conclusion, aluminum extrusions profiles are essential for PCB board level heatsinks due to their high thermal conductivity, efficient heat dissipation, and cost-effectiveness. As technology continues to advance, the need for efficient cooling solutions will continue to rise, making aluminum extrusions profiles a valuable solution to keep devices running efficiently and safely. If you need quality aluminum extrusions profiles, you can contact Renxin Precision via E-mail: sales@renxin-precision.com or Tel: +86(769) 8182 2159.

1. What are Aluminum Extrusions Profiles?

Aluminum extrusions profiles are pieces of aluminum that have been shaped into a specific design using a manufacturing process called extrusion. The process involves pushing heated aluminum material through a die to create the desired shape. The result is a uniform cross-section profile that is strong, easy to handle, and has excellent heat dissipation. These profiles come in different shapes and sizes, making them versatile and suitable for various applications.

2. How do Aluminum Extrusions Profiles Work in PCB Board Level Heatsinks?

Electronic devices generate heat during operation, which can cause damage to the components if not well managed. PCB board level heatsinks are used to help dissipate the heat away from critical components on the board and keep the device running efficiently. Aluminum extrusions profiles are essential in making these heatsinks because they have high thermal conductivity, which helps transfer the heat away from the hotspots on the board. The profiles' uniform cross-section design allows for efficient airflow, dissipating heat faster than other heat sink materials.

3. Benefits of Using Aluminum Extrusions Profiles for PCB Board Level Heatsinks

a) High Thermal Conductivity - The material's high thermal conductivity helps transfer heat away from the hot spots on the board and into the surrounding environment.

b) Efficient Heat Dissipation - The uniform cross-section design of the extruded profile heatsink allows for optimal airflow, dissipating heat faster than other heat sink materials, resulting in better cooling performance.

c) Cost-Effective - Aluminum extrusions profiles are cost-effective compared to other materials used for making PCB board level heatsinks such as copper. They are also lightweight, which makes them easy to handle.

d) Versatility - The profiles come in various shapes and sizes, making them versatile and suitable for various applications.

4. Where to Get Quality Aluminum Extrusions Profiles for PCB Board Level Heatsinks

If you are looking for quality aluminum extrusions profiles for your PCB board level heatsinks, Renxin Precision is your best bet. Renxin Precision is a leading aluminum extrusions profile manufacturer that specializes in producing high-quality extruded profiles. They use modern extrusion machinery to ensure that their products are of high quality and meet the industry standards. They also offer a wide variety of profiles to choose from, depending on your needs.

In conclusion, aluminum extrusions profiles are essential for PCB board level heatsinks due to their high thermal conductivity, efficient heat dissipation, and cost-effectiveness. As technology continues to advance, the need for efficient cooling solutions will continue to rise, making aluminum extrusions profiles a valuable solution to keep devices running efficiently and safely. If you need quality aluminum extrusions profiles, you can contact Renxin Precision via E-mail: sales@renxin-precision.com or Tel: +86(769) 8182 2159.

Leave a Reply

Your email address will not be published.Required fields are marked. *

POPULAR BLOG

- Custom Solutions in Extruded Profile Heatsinks

- Optimizing PCB Performance with Extruded Heatsinks

- Why Aluminum Extrusions Profiles are Essential for PCB Board Level Heatsinks

- Everything You Need to Know About Extruded Profile Heatsinks

- Extruded Profile Heatsinks – The Best Solution for Your Thermal Management Needs

CATEGORIES