Thermal Resistance

The thermal resistance of heatsinks is quoted in K/W (degrees Kelvins per Watt). This value indicates the temperature difference ∆v (in Kelvin) between the surface of the heatsink and ambient depending on the applied power dissipation PV(in Watts).

Thermal resistance quoted is with fins vertical in free air. The characteristic curves for the various shapes are for shapes free-standing vertically and longitudinally in static air. There are no international standards for measuring the thermal resistance of heatsinks, so the values quoted in this catalogue have been measured under near-practical conditions.

Correction factors: bright surface: + 10% , fins horizontal: + 20%

The thermal resistance of the heatsink (RthK) can be found from the curves illustrated for any select working point of the semiconductor. The following relation applies:

Tj -Tu

Rthk= -------- - Rth H

P tot

RthK = thermal resistance of the heatsink (K/W)

RthH = thermal resistance of the semiconductor (K/W)

Tj = junction temperature (°C)

Tu = ambient temperature (°C)

Ptot = Power loss (W)

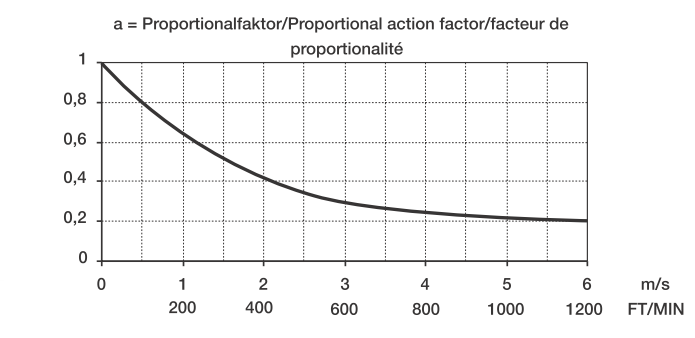

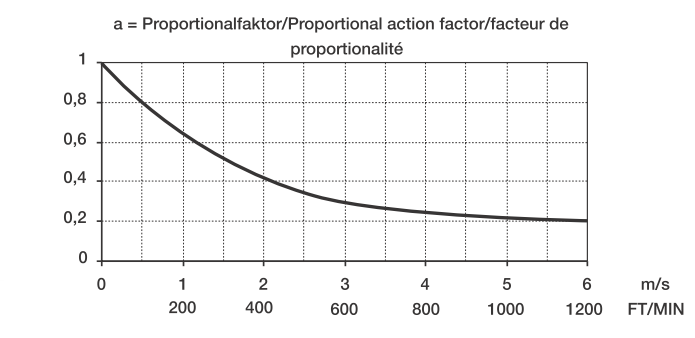

Once a suitable shape has been select the anticipated junction temperature Tj of the semiconductor should be checked using Tj = TG + Ptot x RthH as the housing temperature TG can be measured by simple means.Thermal resistance of random shapes with forced cooling

RthKf ≈ a x RthK

R thKf = Thermal resistance, forced cooling

RthK = Thermal resistance, natural cooling

Principles of Heat Transfer

Heat transfer is a directed transfer of energy between mediums, liquids or gases of different temperatures where the natural flow of heat transfer is from high to low temperature.

Conduction

Conduction is a molecular movement within a medium undergoing a fall in temperature. The conduction and the resultingheat transfer depends on the material involved. The conductivities of materials are expressed as coefficients λ in [ W/mK]

Principles of Heat Transfer

Heat transfer is a directed transfer of energy between mediums, liquids or gases of different temperatures where the natural flow of heat transfer is from high to low temperature.

Conduction

Conduction is a molecular movement within a medium undergoing a fall in temperature. The conduction and the resultingheat transfer depends on the material involved. The conductivities of materials are expressed as coefficients λ in [ W/mK]

| Material |

in (K/mK) |

| Silber |

408 |

| Kupfer |

365 |

| Aluminium |

209 |

| Edelstahl |

15 |

| Luft |

0,02 |

The thermal resistance of a body is expressed in K/W and is dependent on its coefficient and the area and distance of

heat flow. It describes the temperature rise of the body above the ambient for every Watt of power supplied.

Radiation

Radiation is the transfer of energy through electro-magnetic waves in the wavelength range from 0.8µm to 400µm.

As opposed to conduction, radiation is not bound to a transfer medium. It depends on the temperature and surface of the radiating body. Rough bodies radiate stronger than smooth bodies. Radiation increases with temperature of the radiating body whereby dark bodies absorb and emit more heat than light bodies. The following energy retainment formula applies to radiation:

ϕ = reflected quantity

ϕ + α + J = 1 α = absorptivity quantity

J = transferred quantity

ϕ, α und J depend on the material and the wavelengths of the radiation. Radiation from heat sinks is mainly peripheral as radiation between ribs is practically absorbed. To improve heat emission through radiation with natural convection and high surface temperature it is beneficial to black anodize the heat sink as the heat transfer coefficient depends on the ambient medium (air) and the type of heatsink surface and not on the heatsink material itself.

Convection

Convection is heat exchange within liquids, Vaporize or gases through molecular movement from cool to warm areas.

Free convection is brought about by differences of air density caused by different temperatures. Air layers close to the

surface become specifically lighter than deeper layers due to the heat from the heat sink fins. This causes a static pressure difference between the layers resulting in an upward air flow. If the heat seat fins are too close together they warm each other up and restrict free convection. Forced convection (forced cooling) requires a separate convection source in the form of a fan. To achieve optimal convection the heat sinks should be free-standing with vertical fins.

Laminated flow

Laminated flow is air movement in parallel streams or layers with internal friction but without turbulence

Turbulent flow

Above a so-called critical speed a laminated flow changes to a turbulent flow whereby air currents can develop which

work against the flow direction. Turbulent flow is a major factor in achieving good heat dissipation through convection.

Convection is more important in heat dissipation with heat sinks than radiation.

Thermal transfer Before heat can be transferred from a heatsink to the ambient air a thermal resistance must be overcome. The resistance depends on the thermal coefficient of the material and the contact area, whereby the heat transfer is not proportionally increased by a larger contact area but is influenced by the fin construction of the heatsink. The effectiveness of the fins decreases towards their tips where the temperature fall decreases. Heat dissipation through convection can be improved by increasing the air flow, changing its direction and by producing turbulence.

Offers one of the highest quality and most diverse ranges of thermal management hardware in the world

To be able to make a sound evaluation and a better selection of thermal products for use in solving your thermal management

issues, you first need the most comprehensive range from which to make your choice. Renxin Thermal diverse range of the

highest quality thermal products and materials can facilitate in making this decision process easier. Renxin Thermal extensive

product range has defined categories of product types. These have been arranged based on their physical and technical properties

for easier understanding. Deciding on which product best suits your application is crucial to the success and reliability of your

project. Renxin Thermal experienced engineers will gladly review your project and offer a design suggestion and product selection

from our extensive range. Free samples are readily available from our office for evaluation, please do not hesitate in completing

your request for samples as required. Our products are supported by our comprehensive and dependable technical support to help

you make the right engineering and commercial decisions, so feel free to

email an enquiry or call our salesoffice today.

Renxin.Thermal is committed to delivering our customer the most cost effective and reliable thermal solutions available. Products range from heatsinks, Heatsink Design optimization,TEC devices, interface materials and thermal substrates plus many other materials that aim to complete your thermal solution.

Technology Suport :

info@renxin-precision.com