RX580-063-19 Extruded profiles for cooling aggregates 50 [1.97] x 50 [1.97]

Item No.: RX580-063-19

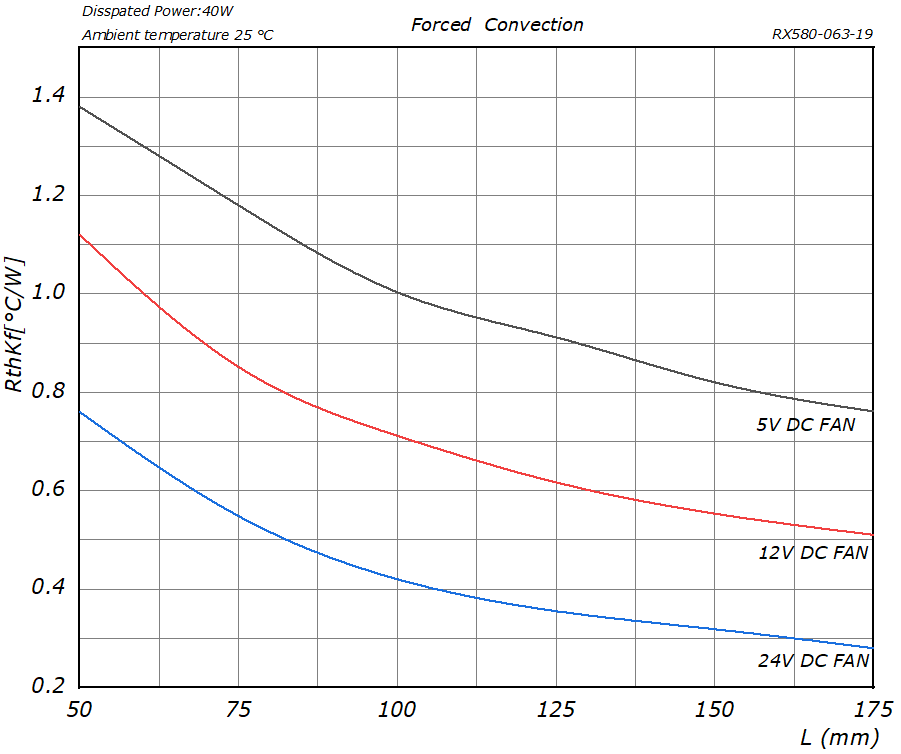

Compact design and homogeneous heat dissipation,Collocation miniature DC fan motor with grooves for lock-in retaining springs, good thermal performance, other lengths, special designs and processing according to customer´s requirements

Login to see price